Tangerine reveals super-fast express freight system designed for Hyperloop TT

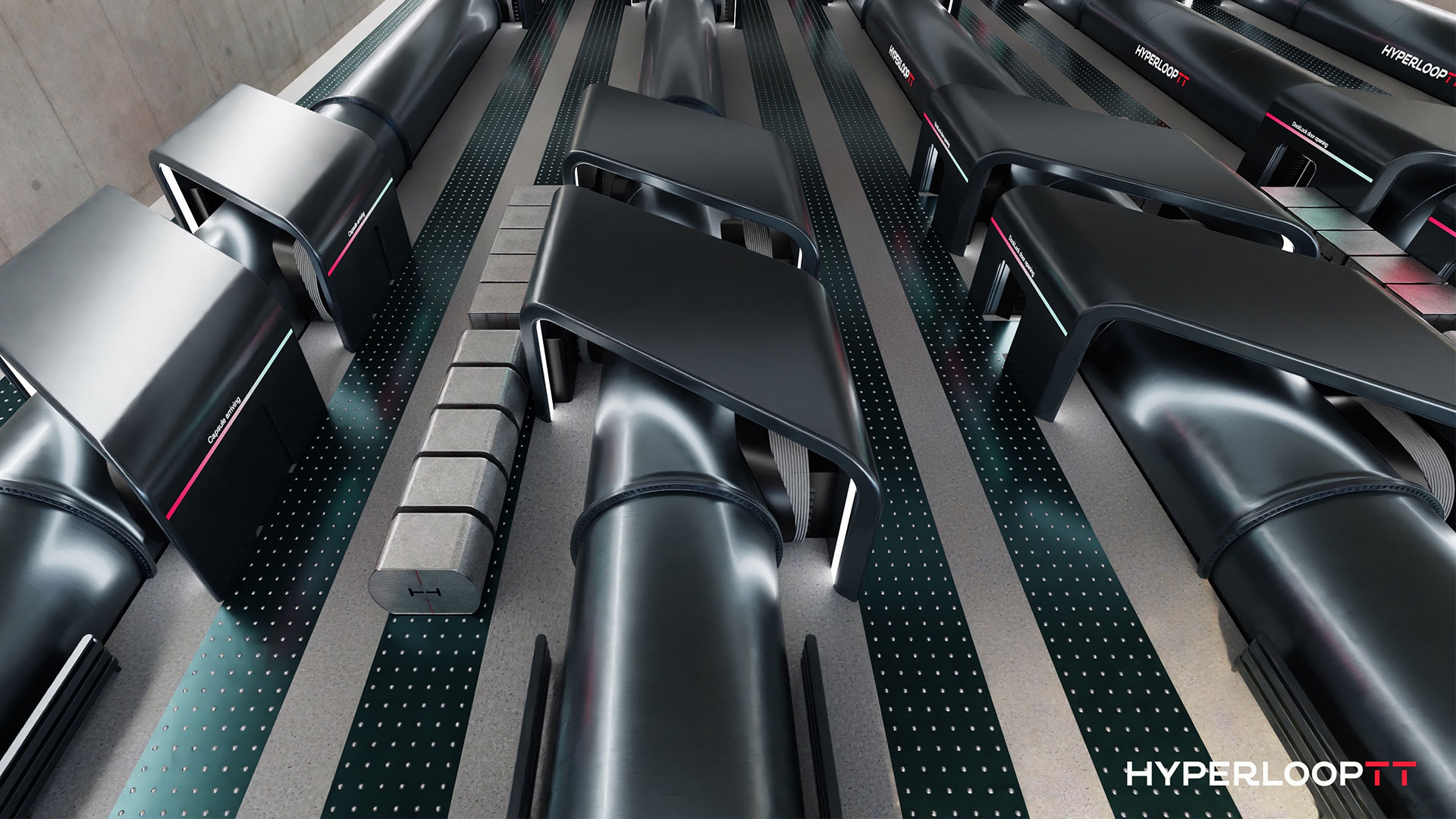

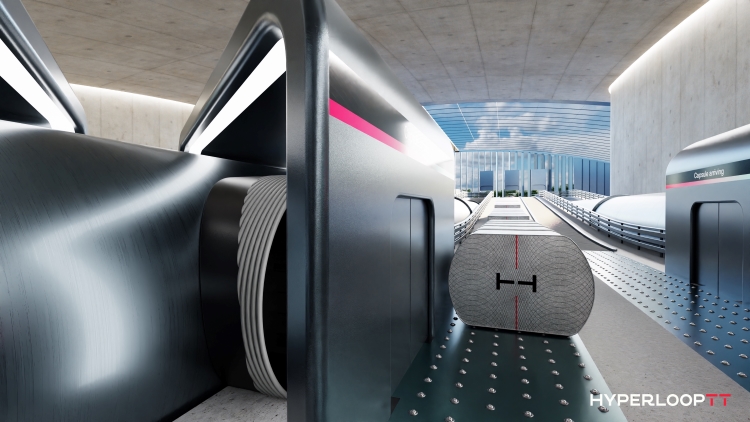

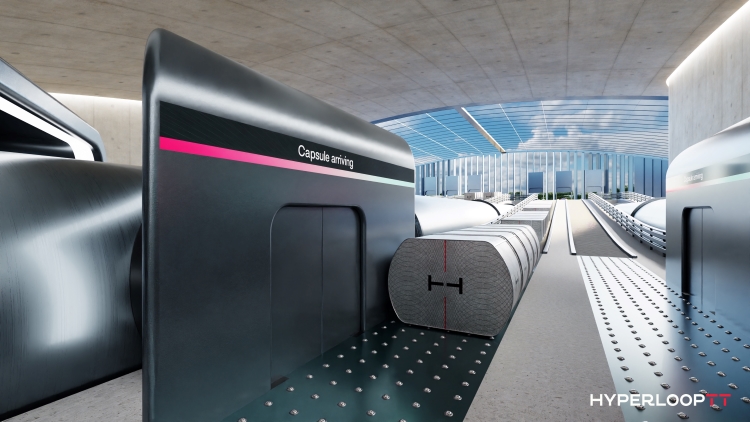

The system involves “up and over sliding doors” in a staggered layout that aim to maximise space inside the capsule and allow for simultaneous loading and unloading.

Tangerine has unveiled its design of an express freight system for Hyperloop TT, capable of loading and unloading freight onto a capsule in 13.2 seconds.

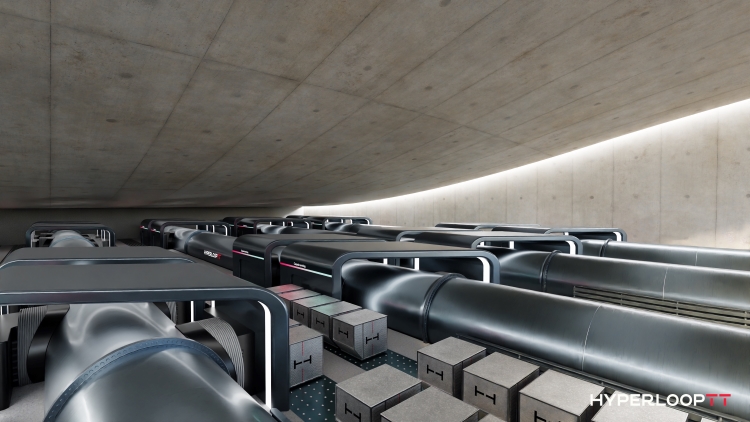

Hyperloop is a high-speed transportation system, similar in size to a small commercial aircraft without wings. It involves pressurized capsules that levitate on a near-frictionless magnetic field within tubes.

While there are several different Hyperloop companies developing services around the world, Tangerine’s client is Hyperloop TT, which claims that its system has “a low implementation cost compared to other high-speed transportation methods”. It describes how its capsules are “engineered and designed for ultra-high speeds using cutting-edge composite materials and safety features”.

The whole proposition for Hyperloop transport is that its “cheaper than air and faster than trucks”, says Tangerine chief creative officer Matt Round. The speed element it not just about how fast the trains travel around countries but also about loading and unloading as fast as possible to make the whole service efficient, according to Round.

The studio was tasked with designing a system for loading and unloading express freight – which is smaller than large cargo containers – into the Hyperloop capsules. Round says he avoided “looking sideways” at competitors and being influenced too much by other industries, and instead spoke to the different stakeholders to understand what was important for this system.

Round defines the four key “design drivers” for the project as: loading the freight as fast as possible; integrating with existing infrastructure; maximising freight volume inside the capsule; and creating a flexible system that would cater to different customer demands.

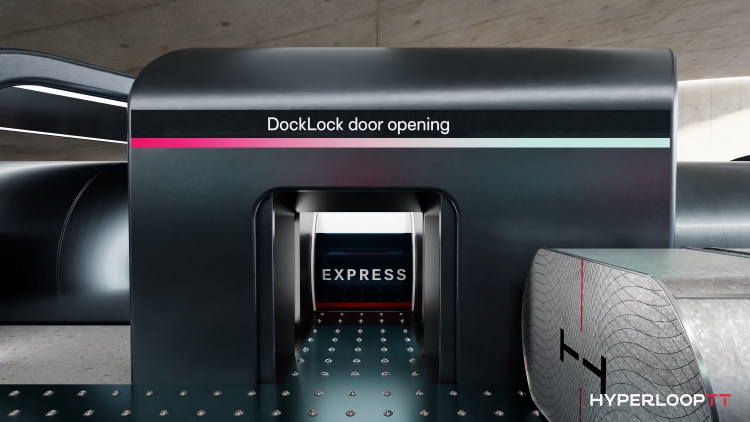

Tangerine senior designer Ryan Braggins explains how maximising freight volume meant testing “different door mechanisms and different sized doors”. He says the studio initially thought to have bigger doors to speed up loading but realised this would “increase the time for the pressurised DockLock to open” and risk changing the conditions of the vacuum.

The DockLock is “an air lock that sucks on to the capsule, equalising the pressure inside and outside the tube”, according to Round. He says that keeping the capsule inside the vacuum and not changing its “atmospheric conditions” makes the “structural capabilities of the capsule last significantly longer” and limits degradation.

Read more: HyperloopTT reveals autonomous freight transport concept HyperPort

Tangerine came up with a solution that involves “up and over sliding doors”, says Braggins, which utilises the rounded shape of the capsule and seeks to maximise the internal space. The layout of the doors was a more challenging element, as Tangerine had to create 3D animations to calculate loading/unloading times, according to Braggins.

He explains how “staggered doors” allow for a “steady constant flow of loading and unloading”. In practice, this means when a capsule arrives into the station, freight can be simultaneously loaded and unloaded. Tangerine calculated that this system can load a capsule in 13.2 seconds, with freight moving at walking speed, from the moment that the airlocks engage and the doors open.

Read more: HyperloopTT repositions around “credible” future

The load devices run across a roller ball flooring system, which is a modified version of a proprietary system by Collins Aerospace currently used inside the cargo hold of airplanes.

Solutions included “leveraging technologies” and “integrating into existing infrastructure” so Hyperloop TT don’t have to “make a completely new piece of technology” every time they create something new, explains Round. He adds that it was an “inviable proposition” to have freight and passengers in the same capsule, however, capsules and tubes of the same diameter are used for both people and freight, meaning more freight can be loaded at times when there are less passengers or vice versa.

A feasibility study around the economics of Hyperloop TT’s plans was carried out in 2019/2020. Round reveals that £698.6 million has been secured to build the first commercial Hyperloop in Northern Italy, just outside Venice, to “prove the prototype”.

Tangerine plans to stay in contact with Hyperloop TT as development

-

Post a comment